In logistics in particular, reliable supply chains are crucial to competitive success. But to ensure that the supply chain remains truly dependable and efficient, technical solutions such as supply management, transport management and dock & yard management are indispensable. If you don't want to lose track of the numerous trucks, resources and processes in your own loading yard, holistic management of dock and yard processes should therefore be at the top of your to-do list.

However, organizing oneself manually quickly becomes a confusing task due to the abundance of different information. Mistakes happen, such as incomplete documentation of the delivery. This can have serious consequences for the customer's supply chain, especially when it comes to materials for further processing. He may not receive them until much too late, has to pause his production, and is ultimately dissatisfied with the entire service. To avoid this, both shipping and supplying companies should urgently ensure transparency in their processes with the help of a Dock & Yard Management solution.

What Is Dock & Yard Management?

Dock & Yard Management describes the management of all resources and logistical operations on the outside areas of a depot or logistics center. This includes the documentation of various information such as arrival and departure times of trucks, real-time location monitoring of vehicles and even the contact details of drivers. The process also involves different parties such as the shipper, supplier, logistics service provider and consignee. The term Dock & Yard Management is composed of "dock" and "yard", both of which refer to a different part of the outside yard.

Dock

Dock refers to the loading area where transport vehicles are loaded and unloaded. Docks do not have a fixed size and can range from conventional ramps to complex systems with additional aids such as loading doors and hydraulic loading bridges.

Yard

The yard area is usually larger than the dock because it is used for storage, sorting and handling of incoming and outgoing deliveries. If necessary, forklifts or cranes are also used there to move the goods.

Dock & Yard in Combination

For a smooth flow of goods, dock and yard are usually closely linked. This enables the transport units to move incoming and outgoing trade goods quickly from one area to the other: From yard to dock to load them into the respective means of transport and vice versa to store or sort them. To ensure that faulty deliveries or damaged products do not go undetected in the process, each work step must be carefully documented.

Which Processes Does Dock & Yard Management Involve?

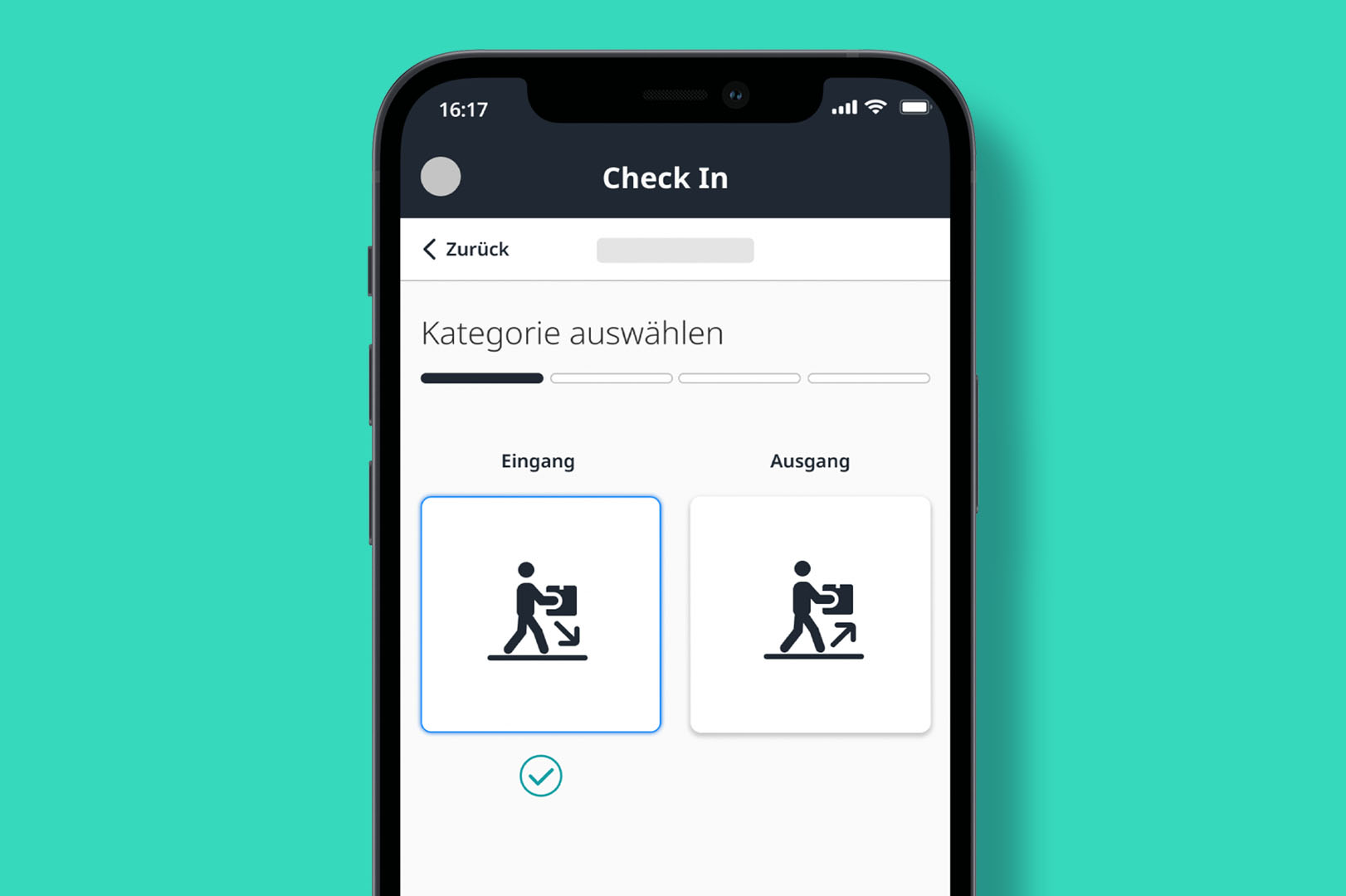

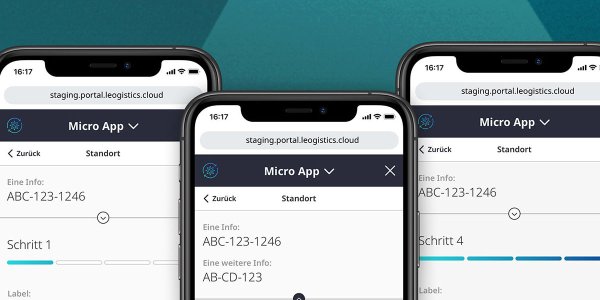

In addition to the direct handling and transport of goods, there are other processes that need to be taken into account for successful dock & yard management: we are talking about transport management and communication with the delivery drivers. This includes planned deadlines, actual arrival and departure times, live locations, and contact information for the delivery driver. To ensure transparency throughout the supply chain, the focus is on the times at which each process was completed. In this way, potential delays become apparent at an early stage and the company can initiate measures to proactively reschedule subsequent work steps.

In addition, appointment scheduling is also an important factor in Dock & Yard Management. This includes the management, monitoring and control of delivery traffic. At best, appoinments are booked online in advance so that all deliveries arrive at the scheduled time in the correct order. Another aspect of dock & yard management is plant security or the safety of employees at work. Especially in traffic and in contact with heavy equipment such as trucks, forklifts or cranes, carelessness can quickly lead to accidents with possible serious injuries. Continuous maintenance of safety equipment, guidelines and established procedures for safety monitoring and assessment are therefore essential. Regular training also prepares personnel for emergencies.

What Are the Benefits of Dock & Yard Management?

Above all, effective dock & yard management strengthens the overview of all inbound and outbound movements within the yard. And this has a massive impact on the entire supply chain. Complete documentation of the information also helps to identify optimization potential and make processes more efficient. With the contact data of the delivery driver, unfavorable misunderstandings can also be clarified in the shortest possible time or faulty deliveries can be avoided. The bottom line is that Dock & Yard Management improves delivery processes and thus customer satisfaction. At the same time, the plant premises remain safe, which not only enables the company to comply with legal guidelines, but also gives employees a good feeling at work. Conversely, the more efficient handling also increases sustainability: because the avoidance of idle times, subsequent deliveries and unnecessary transport routes, as well as the optimal use of storage space, save energy and fuel consumption.

Pitfall: Manual Dock & Yard Management

However, for companies to benefit from all these advantages, dock & yard management must run flawlessly. Manually, this is a barely solvable task, often involving terse notes on paper lists and cumbersome isolated solutions. Even analog calendars, on which access control is handled by e-mail or telephone, are more of a disruptive factor than a help. Since the various parties have to work together quickly and transparently, it all comes down to organization: Incorrect entries delay the process and missed ones cause uneconomical waiting times. There is no overview of which vehicles are currently on the site, whether delays are taking place or which vehicles are still due to arrive. This makes it difficult to schedule personnel to handle goods in a timely manner. Experienced companies meet this challenge with unified systems that replace the many stand-alone solutions and present the entire process intuitively. Software solutions are already common standard at many shippers and the only logical choice compared to manual management.