Suppliers in the automotive industry are often under massive pressure. In many cases, the production of preliminary products at the supplier is also dependent on the production planning of the automotive manufacturer. Due to high cycle times and short planning periods, material orders from suppliers are placed at short notice and statements about the actual quantity that can be delivered are often inaccurate. A digital logistics platform can remedy this situation.

Bottleneck Cargo Space

Loading space is limited and there is usually little time leeway. For this reason, a carrier is often commissioned without specifying the actual loading quantities. The carrier books an appointment for delivery with the supplier before all slots are taken. Since he cannot know what quantities he has to deliver, he only books an approximate time slot length on spec. In many cases, however, the drivers are unable to keep to the booked appointment due to delays and longer unloading times. The capacities are not sufficient and long waiting times arise.

An additional problem is that the drivers are not allowed to wait that long due to their legally prescribed driving and rest times. As a result, they regularly either leave again with the material or unload it outside the plant, which causes additional delays and dissatisfaction on all sides. Furthermore, disagreements repeatedly arise in the area of empties return and the clarification cases with the carriers.

In the worst case, the delays bring production to a standstill and thus jeopardize the delivery dates at the car manufacturer. This not only results in special runs to the OEM and severe penalties, but also has dire consequences for the customer relationship. To counteract this risk, employees at the supplier spend a lot of time trying to obtain better information about delivery quantities and dates. Countless phone calls are made and tracking information is accessed. Another barrier to visibility is often the tools used: E-mails, Excel spreadsheets and manual system entries can only be tracked with great effort.

Switch to Self-Collection

The dependence on third parties makes it incredibly difficult for suppliers to make binding statements about delivery quantities and dates. One solution would be to switch to self-collection, possibly in combination with milk runs. This would ensure production supply and guarantee delivery capability. Employees should be able to concentrate on their core tasks again and be relieved by automated processes.

Transparency and Process Management with a Digital Logistics Platform

The ordering process could be simplified in particular by coordinated communication between the parties involved: The supplier places an order with his subcontractor in the web UI and specifies the desired delivery date. The subcontractor is immediately informed electronically.

The subcontractor then notifies quantities, dates and packaging information via the platform at delivery item level. This information is automatically fed back to the supplier. Now he knows in detail when which material, in which packaging, and in which quantity is ready for pickup. He can now plan transports and commission a carrier.

The carrier is informed about how many packages with which weight are to be transported from where to where and with which date. He is requested to book a delivery appointment. However, the time slot length is no longer arbitrary or can be selected on a hunch, but is calculated by an algorithm based on certain parameters (e.g. material type, quantities, packaging type).

The supplier now has all the information about delivery date, quantity and packaging, and this with direct reference to the order. He can now make a realistic planning based on the actual expected unloading time and on existing capacities - no more can be booked than the free capacities allow. The status messages ("truck is loaded and moving off") from the carrier are also immediately available to the supplier and can be seen in the process document. There is transparency about delivery dates and possible deviations, without having to extend communication between the parties involved to other channels such as e-mail, chats and phone calls.

Settle Dispute Cases Easily on the Basis of Tangible Information

If something does go wrong, a transparent dispute management system is desirable that settles and takes into account disputes between the freight forwarder and the supplier even before the credit note is issued. Since the dispute cases can also be documented directly and digitally at document level with the help of a logistics platform, this is comprehensible and possible without media discontinuity.

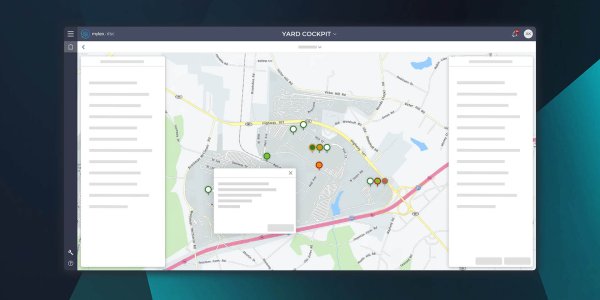

But this is not the end of the story. You can even go one step further in digitalizing and simplifying your processes. The next stage of expansion could even be an inbound control tower to achieve complete transparency from the time the order is placed, through the arrival of the truck, to unloading.

Next Level Inbound Logistics with the Help of a Supply Chain Control Tower

This approach includes the full digitalization of the plant premises and also enables self-registration of truck drivers in their own language, safety instruction on demand, and guidance through the unloading process, including all calls to the respective ramp up to check-out. This self-guided registration process can be implemented on the one hand by self-check terminals, on the other hand by web applications for smartphones or tablets. As a result, all steps are documented digitally and ultimately do not disappear in a file folder on the shelf in the control center.

In this way, the automotive supplier can achieve its goals and overcome its process-related hurdles: He now has the basis to implement milkruns, the peaks in his incoming goods are ironed out, the production supply is thus ensured and the employees have noticeably less manual effort.