In modern logistics, transportation management systems (TMS) and warehouse management systems (WMS) have established themselves as indispensable IT components. However, there is a crucial gap between these two systems: What happens on the company premises when transportation reaches the warehouse? This critical interface is covered by a yard management system (YMS).

What the digital triad of modern logistics is

A complete logistics IT ecosystem consists of three equally important pillars:

- TMS: Manages and optimizes all transport processes up to the factory gate

- YMS: Manages and coordinates all movements on the company premises

- WMS: Organizes and controls the internal warehouse processes

Without an efficient YMS, a media discontinuity occurs precisely at the point where efficiency is particularly important: at the transition of goods transportation into (and out of) the warehouse. A modern YMS closes this gap and creates seamless processes along the entire supply chain.

Why the IT department should prioritize a YMS

While TMS and WMS are often introduced by the IT department, the YMS is often neglected. Yet there are convincing arguments in favor of a yard management system, particularly from an IT perspective:

1. Continuous data chain instead of information silos

A YMS connects TMS and WMS using modern APIs and ensures a continuous flow of information. This reduces manual data input, eliminates sources of error and ensures data integrity across all systems.

2. Core functions according to Gartner recommendations

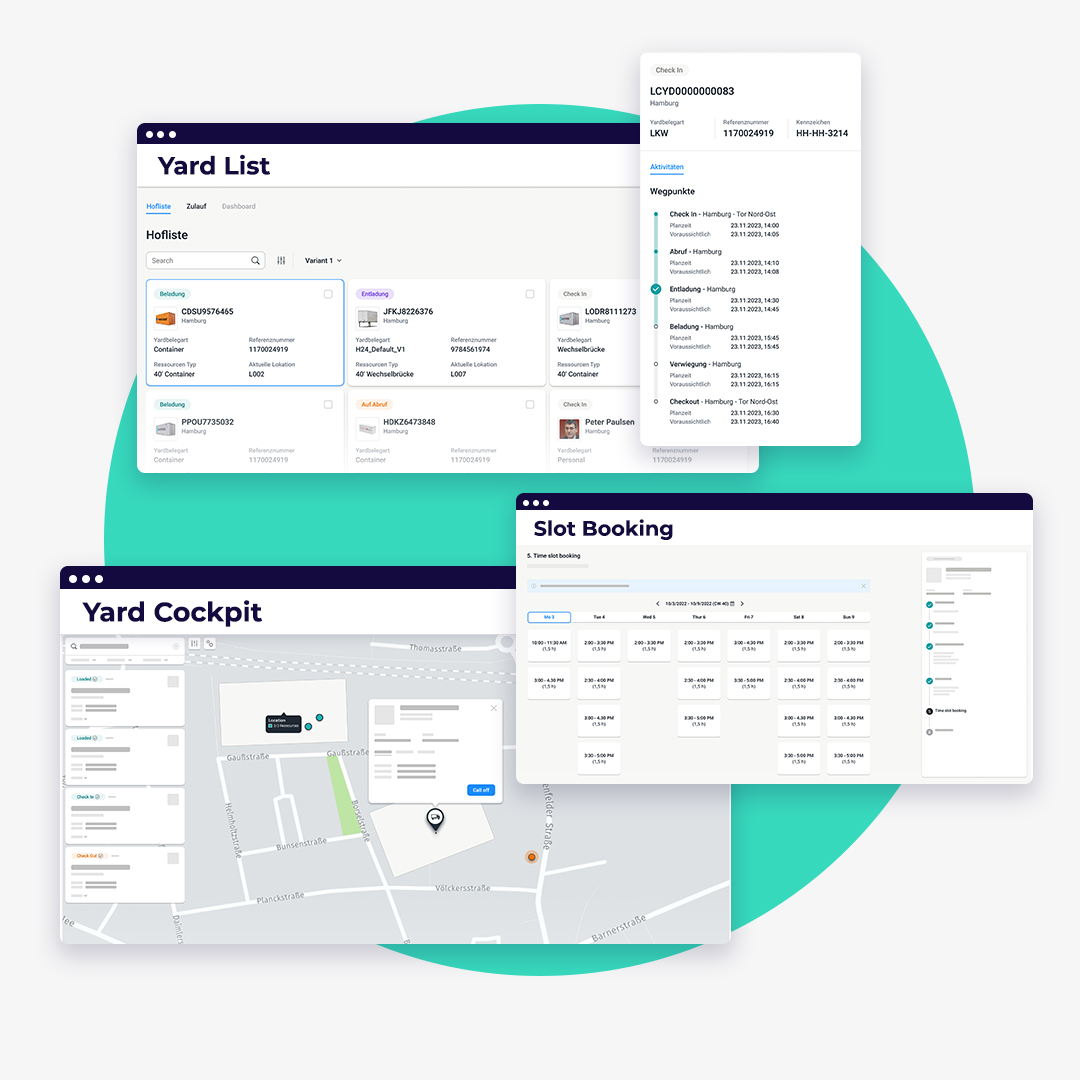

The market research experts at Gartner define clear requirements for a modern yard management system:

- Comprehensive yard visibility (digital twin of the yard)

- Automated gate management

- Intelligent dock scheduling

- Optimized yard movement management

- Powerful business intelligence

- Seamless integration capabilities

- Mobile accessibility

A future-proof YMS fulfills all these criteria and also offers modern IT features such as cloud hosting, scalability and regular updates.

3. Fast ROI with minimal information effort

The return on investment is crucial for IT budget planning. A modern YMS enables a convincing ROI calculation with just a little basic information:

- Number of daily truck movements

- Average time spent on the site

- Current process costs for manual activities

The typical payback period of 12-18 months makes the investment decision much easier for IT decision-makers. Basic functions such as digital self-check-in for trucks or slot management can often even be rolled out by the specialist department without IT capacity and bring enormous added value to the site after just a short time.

4. Reducing complexity through hybrid solutions

Modern YMS providers supply software and hardware from a single source. This has several advantages:

- Reduced interface problems

- Only one point of contact for support and maintenance

- Simplified updates and less integration effort

- Standardized processes for all components

5. Data-driven basis for decision-making

A YMS generates valuable data for strategic decisions in operational logistics:

- Real-time KPIs for yard performance

- Prediction models for resource requirements

- Identification of automation potential

- Sound capacity planning

How you can achieve flexibility in the standard

Especially for internationally operating companies, a YMS offers the opportunity to standardize processes globally while still taking local characteristics into account. A modern YMS should offer the following functionalities:

- Multilingual user interfaces

- Adaptation to regional regulatory requirements

- Scalability for different site sizes

- Configurable workflows for location-specific processes

Conclusion: No complete digitization without YMS

A yard management system is not an optional add-on, but an essential component of the logistics IT architecture. It closes the critical gap between transport and warehouse management and ensures end-to-end digitalized, transparent and efficient processes.

For IT decision-makers, the question is no longer whether a YMS makes sense, but how it can best be integrated into the existing infrastructure. Those who implement a YMS complete the digital triad of logistics and create the conditions for a future-proof supply chain.